Denka is trying to reduce their chloroprene emissions so they can get under the EPA guidelines.

Denka Performance Elastomers, the controversial neoprene manufacturer located between LaPlace and Reserve, is planning to test a new method of temporarily storing waste that will collect high levels of cancer-causing chemicals and destroy them in the plant’s thermal oxidizer. The wastes are described as a coagulant contaminated with chloroprene, which the U.S. Environmental Protection Agency describes as a likely carcinogen. The wastes are created as neoprene is manufactured, and the EPA targeted them because of emissions federal inspectors noted when they visited Denka in April and May. Denka’s plan is to hold up to 30 pounds of the coagulant in a metal cart fitted with a lid that will capture the emissions, according to documents filed by the company with the state Department of Environmental Quality. The lid will be connected to a supply of industrial nitrogen, which will be used to remove chloroprene from the material, and to a closed-vent system at the plant that will route the chloroprene gas to a thermal oxidizer, which will destroy the material. Steam may also be applied to the outside of the cart to help remove the chloroprene.

nola.com

Denka has been illegally traking the waste to a dump not cleared for handling this type of waste.

In a letter granting approval for the tests, DEQ officials said that as long as all the chloroprene is removed, the waste could be considered solid waste and not hazardous waste under the state’s regulations. In their inspection reports, EPA officials suggested the waste material met the federal definition of hazardous waste. Denka has been taking the material to landfills that are not permitted to receive hazardous wastes. In its approval letter for the tests, DEQ said any wastes would have to be properly identified and disposed in a proper disposal facility, based on that analysis. Denka also plans to test a way of avoiding emissions from another storage tank used to hold waste solids it refers to as “popcorn polymer” when the tanks are periodically opened. The proposal calls for removing residual chloroprene from the waste while it’s still inside the tanks. DEQ also gave Denka approval to move forward with other projects aimed at reducing chloroprene emissions, as long as they don’t result in additional emissions of chloroprene or other toxic gases, and they’re listed in pending permit renewal applications.

(Environmental Protection Agency)

The EPA tests earlier this year found the chloroprene in uncovered bins.

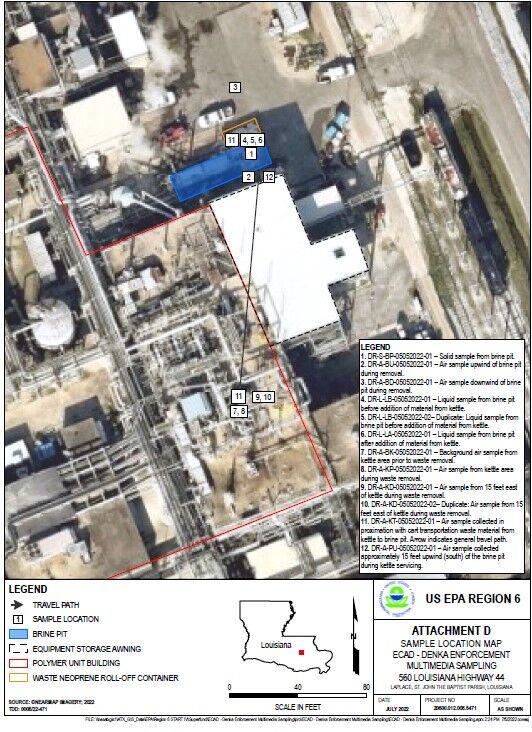

EPA’s April and May inspections and a third inspection in June raised questions about high levels of emissions of chloroprene from Denka’s wastes, then being held in an open bin in an area where workers were not wearing masks. The EPA said the April inspection aimed to evaluate the company’s compliance with federal regulations governing the handling of solid and hazardous wastes. “EPA returned to the facility in May and collected samples (solid, liquid, and air) from waste management areas, many of which showed high onsite concentrations of chloroprene,” said a statement issued by EPA’s Dallas regional office last week. That inspection focused in part on the wastes that Denka’s new storage method will handle. “Consistent with the agency’s mission to protect public health, EPA is considering the use of all enforcement authorities to address emissions at this facility.” EPA officials did not respond to requests for information about a third inspection that occurred in June.

OSHA has also been visiting the plant on inspections.

The federal Occupational Safety and Health Administration opened an investigation of Denka, conducting its own inspection on May 13, a week after EPA’s inspectors reported the unprotected workers. That investigation is ongoing, said OSHA spokeswoman Chauntra Rideaux. DEQ is in communication with EPA “regarding an appropriate response” to the issues raised, said spokesman Gregory Langley. Langley said the agency could not comment on whether DEQ officials discussed Denka’s new waste handling plan with EPA. “LDEQ is not and has not been a party to OSHA’s inspection at Denka’s facility,” he said. Denka spokesman Jim Harris said the company remains confident in “the effectiveness of its personal protective equipment protocols developed to ensure employee safety on site.” He said Denka is working with DEQ to find “effective and feasible projects to further reduce its chloroprene,” and the new cart is just one example.

This all has come about with the EPA’s new focus on looking at damages to minority and poor areas and people.

On Wednesday, EPA’s Office of Environmental Justice and External Civil Rights sent a 56-page “letter of concern” to the state Departments of Environmental Quality and Health. It said the agencies may be violating federal civil rights laws and regulations by allowing Black people to suffer disproportionate impacts from air pollution in Louisiana’s seven-parish industrial corridor, including an increased risk of cancer. The letter focused on Denka and Formosa Plastics’ proposed $9.4 billion project in St. James Parish, as well as emissions from other plants. On July 6, EPA ordered Denka to install a different type of monitoring equipment at three existing stations in a majority-Black neighborhood just west of the plant, including at Fifth Ward Elementary School, at a location on Chad Baker Street, and a location near the corner of East 31st and Spruce streets. Those three stations are part of a network of 18 around the plant. The new monitoring equipment will measure levels of both chloroprene and 1,3-butadiene, another likely cancer-causing chemical. The letter also ordered Denka to continue taking at least one 24-hour sample for those two chemicals and ethylbenzene, toluene, and xylenes at least once every six calendar days at an Entergy substation just east of the plant; at the intersection of La. 44 and the Illinois Central Railroad; at the site near 31st and Spruce; at a site at the Mississippi River levee; at the southwest corner of River Parishes Hospital, and at an existing site in Edgard. Harris said the new monitoring equipment at the three sites near the school has been installed and monitoring information is being provided to EPA, which may publish it on EPA’s site dedicated to Denka. EPA also asked the company to describe the sources and causes of elevated chloroprene concentrations that occurred during fenceline sampling between April 14 and April 28 and flow rates for materials sent to the oxidizer between May 1 and June 30.

Denka should have thought about these changes before they came knowing what they produce and use.