Years ago, off Block Island, a New Orleans firm built a wind farm. Now we want one down and can they replicate it?

Bryan Wilson’s boat leaves a harbor before dawn and heads toward a sunrise shrouded by heavy rain clouds. His destination, 3 miles into the Atlantic Ocean, is barely visible until he’s almost under its massive spinning blades. “Welcome to America’s first offshore wind farm,” Wilson says before taking a breath and rattling off a well-practiced series of facts about the five-turbine Block Island Wind Farm. Its towering steel posts, each twice as tall as the Statue of Liberty, were made in Spain. The 450-ton generator units atop the posts are from France. And the hollow blades — big enough that Wilson has wandered inside them — were shipped over from Denmark. This pioneering effort in renewable energy might not seem especially American. But everything under the waves is pure Louisiana. “The foundations were designed and built in Louisiana,” says Wilson, the farm’s manager. “They’re each 400 tons, and we had them brought by barge all the way from Houma.”

nola.com

We did more for the Block Island farm and I look forward for them to start here.

The state’s contributions don’t end there. Six Louisiana companies, all of which grew out of the offshore oil and gas industry, supplied a small army of specialists — from designers and engineers to ship operators and marine welders — that planned and executed a large share of the $290 million project. “We needed guys with experience, and you’ve got them down there,” Wilson said. “Building one of these on land is tough enough. Building it out in the middle of the ocean is a whole ’nother thing. It’s a really daunting engineering and logistical task. But that’s what the oil industry has been doing for more than 50 years down there.”

Wind energy is not what you would think about in Louisiana yet one is programmed.

It might make the solidly red state blush a deeper shade, but Louisiana is quietly becoming a powerhouse in a burgeoning “green” industry. Louisiana’s roots in offshore oil production have given it an edge in projects much larger than the Block Island Wind Farm. Offshore wind farms, some with 12 times as many turbines, are taking shape in six more East Coast states, and Louisiana companies are in the mix, supplying surveyors in Virginia, engineers in Maryland and shipbuilders for projects in New York and Massachusetts. The Biden administration’s ambitious plans for combating climate change hinge on the rapid growth of the offshore wind industry. The president has signed an executive order expanding opportunities for the industry and setting a goal of producing 30,000 megawatts from offshore wind by 2030, enough to power 10 million homes.

How long will it take until we see something?

Turbines could start sprouting up in the waters off Louisiana and Texas within the decade, giving the region’s ports and manufacturers a market that’s much closer to home. Offshore wind in the northern Gulf of Mexico could generate nearly 510,000 megawatts — twice the energy consumed by the five Gulf states, according to a recent federal study. Gov. John Bel Edwards has made the prospect of wind power in the Gulf a key part of his new Climate Initiatives Task Force, which aims to cut statewide greenhouse gas emissions by at least 25% by 2025 and reach “net zero” by 2050. “There’s no better example of how improving the environment and the economy can go hand in hand than offshore wind development,” Edwards said at the start of “Wind Week,” a series of online presentations his office sponsored in June. “I want the Gulf and Louisiana to remain essential to our country’s energy story while also doing our part to avoid the worst impacts of climate change.” The oil and gas industry was for decades the state’s strongest creator of jobs and wealth, but many big companies are pulling up stakes, shedding workers and abandoning oil wells at a record rate.

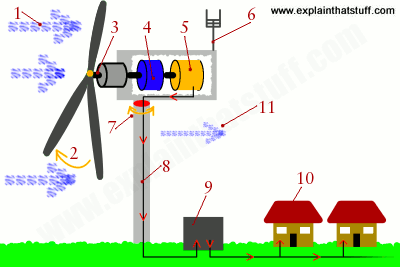

How does a wind farm work?

- Wind (moving air that contains kinetic energy) blows toward the turbine’s rotor blades.

- The rotors spin around, capturing some of the kinetic energy from the wind, and turning the central drive shaft that supports them. Although the outer edges of the rotor blades move very fast, the central axle (drive shaft) they’re connected to turns quite slowly.

- In most large modern turbines, the rotor blades can swivel on the hub at the front so they meet the wind at the best angle (or “pitch”) for harvesting energy. This is called the pitch control mechanism. On big turbines, small electric motors or hydraulic rams swivel the blades back and forth under precise electronic control. On smaller turbines, the pitch control is often completely mechanical. However, many turbines have fixed rotors and no pitch control at all.

- Inside the nacelle (the main body of the turbine sitting on top of the tower and behind the blades), the gearbox converts the low-speed rotation of the drive shaft (perhaps, 16 revolutions per minute, rpm) into high-speed (perhaps, 1600 rpm) rotation fast enough to drive the generator efficiently.

- The generator, immediately behind the gearbox, takes kinetic energy from the spinning drive shaft and turns it into electrical energy. Running at maximum capacity, a typical 2MW turbine generator will produce 2 million watts of power at about 700 volts.

- Anemometers (automatic speed measuring devices) and wind vanes on the back of the nacelle provide measurements of the wind speed and direction.

- Using these measurements, the entire top part of the turbine (the rotors and nacelle) can be rotated by a yaw motor, mounted between the nacelle and the tower, so it faces directly into the oncoming wind and captures the maximum amount of energy. If it’s too windy or turbulent, brakes are applied to stop the rotors from turning (for safety reasons). The brakes are also applied during routine maintenance.

- The electric current produced by the generator flows through a cable running down through the inside of the turbine tower.

- A step-up transformer converts the electricity to about 50 times higher voltage so it can be transmitted efficiently to the power grid (or to nearby buildings or communities). If the electricity is flowing to the grid, it’s converted to an even higher voltage (130,000 volts or more) by a substation nearby, which services many turbines.

- Homes enjoy clean, green energy: the turbine has produced no greenhouse gas emissions or pollution as it operates.

- Wind carries on blowing past the turbine, but with less speed and energy (for reasons explained below) and more turbulence (since the turbine has disrupted its flow).

https://www.explainthatstuff.com/windturbines.html

Back to the story after that Just in Time training!

Long time oil companies and personnel are shifting to wind power jobs.

Joe Orgeron’s family benefited from the initial boom. His father built a prosperous business running supply ships to some of the first oil platforms that appeared off the Louisiana coast in the 1940s. But with work drying up in recent years, Orgeron began turning his fleet in the direction of offshore wind. Now the Galliano-based family business does nothing else. A Republican who was elected to the state House of Representatives last year, Orgeron isn’t trying to save the planet. He’s trying to keep people employed. “All of us that have been in oil and gas, we all need to look at switching to wind, because the question of ‘if’ or ‘when’ wind will happen has long since passed and gone,” he said. “Wind development is happening all up and down the East Coast, and it’s only a matter of time before we have turbines in the Gulf, spinning in our own backyard.”

It also applies to those building the oil platforms as oil dries up.

Eight years ago, Kirk Meche was promoted to CEO of Gulf Island Fabrication, a company that specialized in building the towering foundations for offshore oil platforms. It was a robust business, with more than 1,500 employees and five sprawling yards in Houma and south Texas. But projects kept getting delayed or canceled. Instead of going out to sea, some completed foundations gathered dust. Meche was used to the oil industry’s ups and downs, but he could always bank on the eventual up. “Lately it’s just been down,” he said.

The Gulf area has been in the oil business for a long time and the switch to renewables is timely.

About 15 years ago, before the shale oil boom in west Texas and North Dakota, about a quarter of all U.S. oil production came from the Gulf. Now the Gulf’s contribution is 15%. Once Louisiana’s largest and best-paying industry, oil and gas now employs just 1.5% of the state’s workforce. In Houma and Lafayette, longtime hubs for companies that support drilling, the number of oil and gas jobs has been cut in half over the past decade. Many companies never needed to diversify until now. “We’ve all been looking for alternative means of generating revenue,” Meche said. “So we in Louisiana should be thinking, ‘What part of this wind energy solution can we take part in? How can we be a part of this massive industry?’”

There is amazement about the oil companies switching to wind but were we in Europe we would see another picture.

The U.S.’s offshore wind industry is a baby compared with the behemoth on the other side of the Atlantic. Pioneered by Denmark in 1991, the industry in Europe has been nothing short of explosive. The continent’s annual offshore wind energy output has quadrupled over the past eight years, growing from 6,500 megawatts in 2013 to today’s 25,000 megawatts. Meche knew wind turbines would crop up eventually in the U.S., and they’d need foundations when they did. He struck on the idea of crashing a few renewable energy conferences. “At the first one, we were the oddballs,” he said. “People were saying, ‘Here come the oil guys trying to get in the sector?’ We turned some heads.” Meche caught the eye of the small company that had dreamed up the Block Island farm. Gulf Island didn’t make the single-post “monopile” structures favored in Europe, but it could furnish a four-legged, latticed foundation, also known as a jacket, that it had made so many times for oil platforms. “When you look up, wind is a totally different technology. But when you get below the water, the needs are very familiar,” Meche said. Around the same time, Orgeron’s company was hired by a scientist to do a survey off the East Coast. Word got out among the handful of offshore wind startups. “In one day, I got calls from three different offshore wind companies wanting to utilize my boat,” he said. “I knew that if I didn’t see that as a strong signal, I didn’t deserve to be in business.” By 2014, Orgeron’s boats were busy on the Block Island project. His role grew when an East Coast contractor had trouble installing Gulf Island’s foundations. “What they were trying to do was borderline hazardous,” Orgeron said of efforts to try to drive pilings from an anchored but unstable barge. To finish the job, Orgeron brought in a lift boat, a common Gulf vessel that can drop towering legs down to the seafloor. The East Coasters moved their barges out of the way, “and we nailed it down,” Orgeron said.

Europe met Louisiana, not the US!

It was quite a team: a host of Europeans supplying the above-water turbine components and a bunch of Cajuns doing the rest. “We had meetings with people from Louisiana, Denmark, Spain and France, and the only ones who couldn’t speak English were the guys from Louisiana,” Wilson joked. “I couldn’t understand everything they said, but great guys to work with.” Working in the cold, rough seas of New England wasn’t easy, but Meche said his fellow Bayou Staters adapted quickly. “I call it that Cajun ingenuity,” he said. “It’s a can-do, will-do attitude.” There was some complaining about the food, though. Rhode Island cuisine struck the Louisianans as painfully bland. The state’s traditional clam chowder recipe, for instance, skips the cream, leaving a clear broth that tastes not unlike hot seawater. “Nothing was spicy enough,” Wilson said. “They kept threatening to make us Cajun lobster. Don’t know if I’d want that.”

With help from Louisiana the Block Island project was completed.

The Block Island project finished up in 2016 and now produces 30 megawatts. It’s considered a pilot project, aimed mostly at demonstrating that offshore wind energy is viable in the U.S., but it drastically cut power bills on Block Island while meeting all of its energy needs, both for the 1,000 year-round residents and the several thousand people who vacation there during summers. There’s also enough left over to cover about 1% of Rhode Island’s power supply. The project was transformational for several Louisiana companies. Meche was hired by Morrison Energy, another Houma offshore oil and gas contractor, to do essentially what he did for Gulf Island: “I try to take the assets we have and convert those assets to support wind energy,” he said. Orgeron started 2nd Wind Marine, a company that has designed a new lift boat specifically for the offshore wind market. The vessel will be able to carry the much larger blades that wind farm developers envision on the East Coast. Edison Chouest Offshore, a shipbuilder in Cut Off, was hired by Danish offshore wind powerhouse Orsted to build the first offshore wind service vessel in the U.S. Big enough to house 60 workers, the 260-foot-long ship will allow longer work periods in deeper water. Its first jobs will likely be at three proposed wind farms off the coasts of New York and Massachusetts. Mandeville-based Keystone Engineering has parlayed its experience on the Block Island farm into several offshore wind enterprises. Keystone designed the Block Island foundations, a task that might seem straightforward for a company with experience developing many oil and gas platforms. “I wish it was that simple,” Keystone engineer Sara Ghazizadeh said. “But a big challenge is you’re applying a huge amount of load (with wind turbines) that you aren’t applying with oil and gas.” Keystone had to develop new software, wade through complex European turbine design codes and test 20,000 scenarios involving waves, wind speeds and various other overlapping environmental conditions. “Since then, our involvement in wind has gotten bigger and bigger,” Ghazizadeh said. Keystone has added more than 20 engineers and designers who work almost entirely on offshore wind projects. Keystone now has a renewable energy division that’s expanding beyond wind to solar and battery storage projects.

All of this is getting notice from the oil companies.

Orgeron said other oil and gas-dependent companies, from riggers to sling manufacturers, are starting to notice there’s good money and a bright future in wind. “Not a week goes by that I don’t get a call from an oil and gas services company that’s wanting to get their feet wet,” he said. Not all Louisiana companies have had the best luck with wind, though. Aries Marine, a lift and supply boat company in Lafayette, opened a division in New Jersey to capture more offshore wind business. “I’m hoping that it will happen, but it’s been slow,” Aries President Court Ramsay said. Orgeron, too, has felt the industry’s pace change in recent months. Investment in his new ship business hasn’t come through at the speed he’d forecast.

The problem here is that renewables were slow in getting started. Politics and financial support goes to oil. Oil was king, just look at the death throws now. Even in congress those who got funded by oil keep supporting oil as if it still has a strong future.

Part of the apparent slowdown for some Louisiana businesses stems from increased competition. European companies, which have had a 20-year head start and benefited from generous government subsidies during the industry’s early days, now see a viable market in the U.S. They’re entering the U.S. offshore wind industry with ready-built processes and business relationships.“They want to use all their European buddies … and they want to do it their way,” Orgeron said. If Louisiana companies aren’t getting as big a share of upcoming projects, there’s still plenty of opportunity in “downstream jobs” like surveyors, rust removers, painters and boat operators, he said. Another bright spot on the horizon is the development of offshore wind in the Gulf, a region Louisiana companies could — and should — dominate, Orgeron said. “There’s going to be another barrage of interest when it starts heading to the Gulf,” he said. “Companies here — they need to not turn a blind eye.”

A long story but one that will move in the direction of renewables. Louisiana has wind and solar and should be in a good position. The best part is that the air will get cleaner.