The professor says we make it so capture it.

Carbon capture represents a significant economic opportunity for Louisiana, in part because the state already emits so much carbon dioxide, an LSU chemical engineering professor said Thursday. “There’s a lot of byproduct CO2 that we just emit right now that if you had a way to sequester it here in Louisiana, it’s a pretty good situation economically,” said John Flake, the former chair of LSU’s chemical engineering department and a researcher with the H2theFuture “green” hydrogen initiative spearheaded by GNO Inc. Flake made his remarks during a keynote presentation at TEC Next, a Baton Rouge industry technology and networking conference. The two-day event is hosted by the Greater Baton Rouge Industry Alliance and the Baton Rouge Area Chamber and sponsored by ExxonMobil.

nola.com

There is a constant battle between industry and environmentalist on carbon emission.

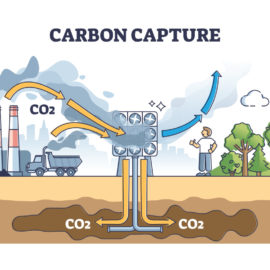

Global carbon dioxide emissions, particularly from heavy industrial sectors, have come under fire over the last several years, in part because of the 2015 Paris agreement that guides global climate change efforts. That scrutiny is also ramping up in Louisiana, where two-thirds of the state’s greenhouse gas emissions come from heavy industry. Louisiana’s climate action task force released a report last year that outlines emission-reducing plans, including carbon capture. Carbon capture is a process by which industrial emissions are trapped on site and injected deep underground. Industry advocates have vouched for the tool as a necessary emissions management technology, while environmental groups and residents near proposed facilities have questioned its effectiveness and safety.

Again, jobs but we do lead in emissions.

Flake said that, according to estimates he has seen, the carbon capture industry could create up to 155,000 direct jobs in Louisiana and 1.76 million temporary jobs. Flake noted Louisiana is a global leader in carbon dioxide emissions per capita. Though the global per capita average for carbon dioxide emissions is about 4.5 tons per year, that figure skyrockets to 50 tons per year in Louisiana. Some chemical production methods in Louisiana already output pure carbon dioxide that easily could be captured, Flake said. Examples include ethylene oxide, a hazardous material used to create medical sterilizers, agricultural fumigants and other specialty chemicals; and ammonia, a key fertilizer ingredient. The economic opportunities arise from new, job-producing carbon capture projects, as well as higher carbon sequestration tax credits, Flake said. The Inflation Reduction Act increased those credits to $85 per ton of carbon dioxide captured. “You’re looking at $10 billion of investment that goes into the plant,” Flake added. “You’re looking at tons of jobs.”

One industry was cited that is emitting and capturing at the same time.

As an example, Flake highlighted the CF Industries ammonia plant in Donaldsonville, the state’s largest greenhouse gas emitter at 10 million tons of carbon dioxide annually. CF Industries is already developing a project to sequester about one-fifth of the plant’s emissions annually. “If you’re already getting CO2 from your process, and you don’t have to pay anything extra besides the transport to the injection site and the injection itself … you’re looking at a profit of about $75 per ton,” Flake said. Louisiana has four key strengths in the carbon capture space, Flake said. Those include infrastructure, technical expertise and available byproduct carbon dioxide, as well as a geology suited for carbon sequestration. However, Texas and Alberta, Canada have similar strengths, Flake said. Some facilities in Alberta are already sequestering carbon dioxide. The state is at a “critical juncture” to take advantage of the economic opportunities in both carbon capture and hydrogen, Flake said. “We can translate these advantages into economic growth and a more sustainable way of life,” he said.

Hydrogen with many uses was discussed.

Flake also spoke about the potential of hydrogen as a fuel, feedstock and energy carrier for Louisiana’s industrial corridor. Hydrogen is heavily used by Louisiana’s oil refineries to develop low-sulfur fuels and by ammonia producers to create ammonia. The standard process to create hydrogen, known as steam methane reforming, is carbon dioxide intensive. Interest is swelling in lower-carbon forms of hydrogen, including “blue” and “green” hydrogen. “Blue” hydrogen is created when carbon capture is used to reduce carbon dioxide emissions, while “green” hydrogen requires electrolysis — the use of electricity to split water into hydrogen and oxygen — powered by renewable energy. Chemical plants that rely on methane as a fuel can easily switch to “blue” hydrogen, Flake said. Hydrogen can also be used as a fuel for large freight vessels such as trucks, cargo ships and trains, though it would require larger tanks than those for gasoline. “You might switch to hydrogen just because it’s easier to sequester the CO2,” Flake said.

This is what the state wants and so maybe a publicity tour is in effect.